The Empire State Building is located in Midtown Manhattan in New York City. Standing 1,250 feet tall (1,454 if you count the spire and antenna), this Art Deco-style structure was built in 1930 and is often featured in TV shows and movies, cementing its status as a cultural icon. With over 4 million visitors annually, the Empire State Building remains a peak tourist attraction to this day.

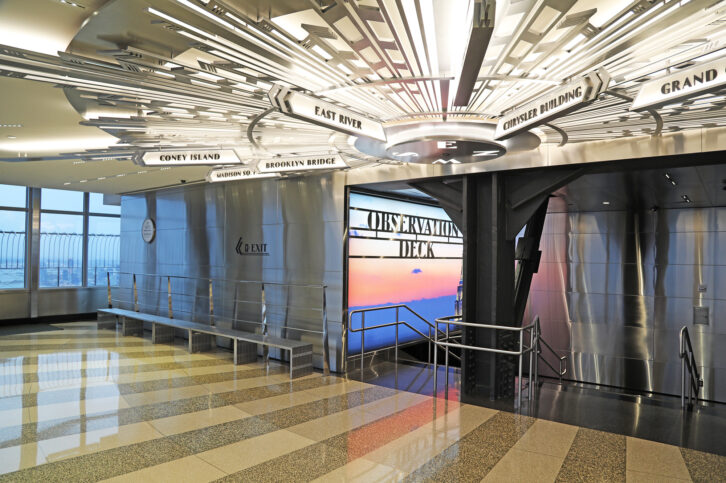

Within the Empire State Building, there were two phases of projects to complete. The first was a gift shop build-out on the second floor in 2018, and the second was “Showtime Retrieval” casework and corridor arches on the 80th floor in 2019.

01

Challenge

Both projects within the Empire State Building were extremely unique—unlike anything TJ Hale had ever done before. We had to build fixtures from various materials that needed to be able to break down small enough to fit inside the building’s undersized freight elevator. Moreover, the merchandise displays were built to be freestanding and self-supporting so as to not extensively tie into the building’s perimeter walls.

Having to make delivery during off hours and share the building’s small elevator was a challenge, especially when transporting materials up to the 80th floor. For two carpenters to bring a small load of product up and make it back to the loading dock could take as long as an hour.

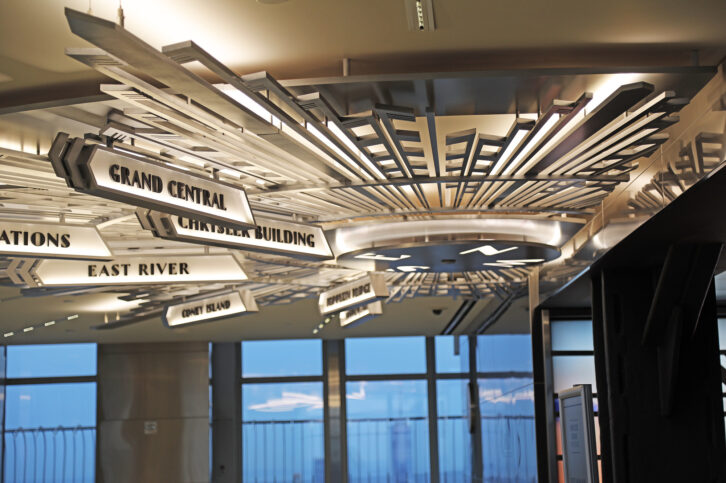

The corridor arches on the 80th floor were also a significant challenge in part because of their large size. They also consisted of components that were difficult to modify and required precise alignments. The arches required access to mechanical, electrical, and plumbing (MEP) elements located above them, thus requiring removable access panels.

Flooring deviations and material and assembly tolerances combined for a challenging array of complications that we dealt with in real time.

02

Approach

TJ Hale’s project management and engineering teams worked closely together throughout the drawing process to collaborate and ensure that the building’s unique requirements were met. This ensured a relatively quick design, approval, and release.

Our team also owned the complete fixture and structure within the fixture, which ensured an accurate fit within the space and other trades components. We handled many abnormal components to provide an all-encompassing solution, including wood, glass, metal, stone, lighting, signage, fabric, and other materials.

03

Solution

TJ Hale partnered with H.J. Martin and Son, a reputable nationwide union installation subcontractor, to successfully navigate, install, and overcome the unique challenges of this project. Due to the nature of the unloading conditions, we staggered our trucks, bringing in only the components we needed for the following couple of shifts. This allowed us to work efficiently without choking out the site with materials.

We modeled the entire fixture space, which allowed us to provide benchmark layouts to various trades and made it easier to come together in the end. We also made templates for the embed steel, which were sent out into the field for coordination and allowed us to set precise layout locations for future fixture placement.

04

Results

Perimeter display walls

Electrified wall standards with integrated clip in lit shelves

Faceouts, hangbars, and peg hooks

Lower drawer units for merchandise storage

Poster board displays

Glass showcases

Light boxes

Rotating merchandise displays

Decorative metal ceiling grids

“Empire on 5th” portal with lit signage

Point of sale (POS) checkout millwork

Anodized aluminum in “Buffed Stainless Steel” and “Buffed Satin Brass”

Formica ColorCore® Laminate

Wilsonart® Solicor™ laminate

Móz™ Metal Laminate

Cambria® Quartz

LED lighting

Krion® Solid Surface

Corian® Solid Surface

Forms and Surfaces® color-fused metal paneling

Stainless steel

Brushed brass

The Latest